|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Track bar, Take 1, Step 2: Cut out section out of 1/4 inch plate. Holes aligned perfectly - first time for everything.

|

|

|

|

|

|

|

|

|

|

|

I notched out some 2.5" x 2.5" 0.25" thick mild steel tube and tack welded it to the plate.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Draft Setup: For the '77, the BC Broncos adjustable track bar had to be "dialed out" more than I'd like (too many threads showing), but it will probably be O.K.

|

|

|

|

Note that the square tube and plate are somewhat at an angle. The track bar and frame are not really parallel up front, so this reduces binding somewhat.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Track bar brace, take one: Angle iron cut and ever so slight bended an rewelded to mount flush on the track bar and the engine crossmember. I will probably rework the brace later as I will probably have to relocate it, as you see later.

|

|

|

|

|

|

|

|

|

|

|

|

|

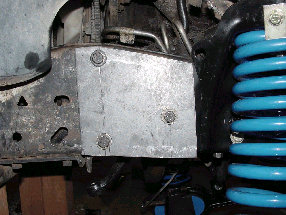

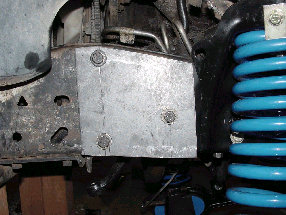

I took the track bar bracket assembly to a welder when I brought the 9" in to have the perches "fully" welded on. All I have is a little 110 mig, and I am not much of a welder. Pic shows welded and painted bracket and brace.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With my little picture, its hard to see, but the track bar and drag link angles are pretty close. The track bar is about 3/8" shorter than the drag link, not sure how I did that, cause I was trying to get them exactly the same. Hopefully it won't be much of an issue. The brace extends horizontally to the crossmember, but as I will have to do some crossmember trimming for clearance, the brace will likely be cut and angled upwards.

|

|

|

|

|

|

|

|

|

I will add an upper bolt to on the right hand side to better secure it to the frame. The bracket looks pretty close to the coil in the picture, but I am 99.9% sure it will never hit.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brief discussion on steering: There are several options. After some discussion with people at rrorc.com, I decided on using 1 ton chevy tie rod ends mated with 7/8" I.D. tubing. This is discussed here:

![Note: no space for the text!]()

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chevy Tie Rod Swap

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This link proved to be very helpful, and contains a link to aid in acquiring the necessary tools and materials.

|

|

|

|

|

|

|

|

|

|

|

|

Complete Offroad

|

|

|

sells most of the required tools, also.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other options using either heavy-duty tie rod ends or heims are likely choices. Some "Brand-Name" options include:

|

|

|

|

|

|

|

|

|

|

|

|

|

Rockstomper Steering

|

|

|

Performance Unlimited Steering

|

|

|

|

|

|

|

|

|

|

|

|

|

|

It is also possible to cut the drag link on a stock E.B. T-style linkage to work with the pre-'76 EB axles.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Most steering setups will require reaming or drilling out the knuckles and pitman arm. Note: The tools ain't cheap. I bought the reamer and reamed the knuckles, but I had a hard time finding an affordable left hand tap, they tend to be $100+ and no one would sell me the DOM tubing in less than 20' sticks. So I bought the cut and threaded chromoly tubing from a local 4x4 shop, cut to my specs (~$100). I need to have a new drag link tube cut, to allow for more thread engagement, 'cause I erred on the too short side of things here. Its hard to see in the small picture, but I have way too much thread showing. Maybe someday I'll make them thumbnails to bigger pictures if anyone wants them. In any case, steering options abound, some cost more money than others.

On a final note about steering, my tie-rod ends smacked the wheel weights on my rims, due to the wide-spaced knuckles on the '77 EB d44. I bought 1/4" wheel spacers from BC Broncos to solve that problem.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Back to page 2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

On to Page 4...

|

|

|